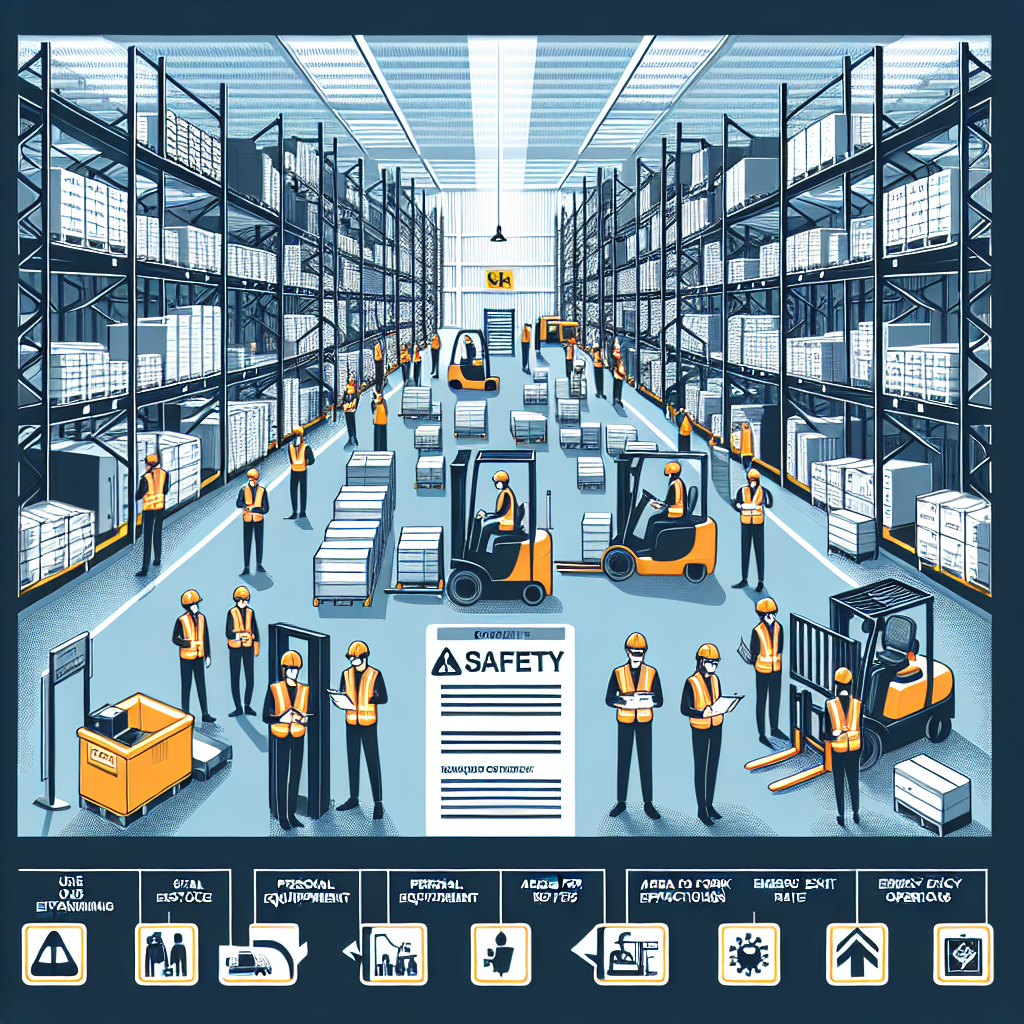

Warehouses serve as the backbone of supply chain operations. With a blend of efficiency and safety, businesses can ensure that products move seamlessly from the manufacturer to the consumer. However, with the sheer volume of activity that takes place in these spaces, it is imperative to uphold safety standards to prevent accidents and enhance operational efficiency. In this article, we’ll explore essential safety guidelines that not only safeguard workers but also optimize warehouse efficiency.

Understanding the Importance of Safety in Warehousing

Before delving into safety guidelines, it is crucial to appreciate why safety is paramount in a warehouse setting. Workplaces that prioritize safety tend to experience fewer accidents, leading to less downtime and higher productivity levels. Additionally, a culture of safety fosters employee morale, as team members feel valued and protected.

Investing in Quality Training Programs

The Need for Comprehensive Training

The foundation of warehouse safety begins with employee training. Investing in comprehensive training programs ensures that team members know how to safely operate equipment, understand hazardous materials, and follow proper lifting techniques. Regularly updating training content to reflect current regulations and technologies can significantly lower accident rates.

Emphasizing the Use of Personal Protective Equipment (PPE)

Encouraging the use of personal protective equipment (PPE) represents a core safety commitment. Make it mandatory for employees to wear hard hats, gloves, safety goggles, and appropriate footwear while working in the warehouse. Ensure that PPE is provided at no cost to workers, reinforcing the company’s dedication to their safety.

Implementing Effective Warehouse Layouts

Streamlined Operations Start with Design

An orderly warehouse layout contributes significantly to both safety and efficiency. Organize storage areas logically to minimize unnecessary movement. Consider using vertical space to decrease clutter and ensure pathways are wide enough for forklifts and other machinery.

Designated Work Zones

Creating designated work zones helps reduce the risk of accidents. Mark specific areas for loading and unloading that are separate from regular foot traffic paths. Clear signage and floor markings not only help direct traffic but also remind employees to remain vigilant in high-risk areas.

Utilizing Technology for Enhanced Safety

The Role of Automation

Investing in technology such as automated guided vehicles (AGVs) and warehouse management systems (WMS) can dramatically enhance both safety and efficiency. Automation reduces human error, as machines handle repetitive and potentially dangerous tasks.

Regular Maintenance Checks

Utilizing software solutions can facilitate timely maintenance checks on machinery and equipment. Ensuring all tools are in optimal working order can prevent malfunctions that could lead to accidents, thereby enhancing overall warehouse efficiency.

Regular Safety Audits and Inspections

Continuous Improvement through Audits

Instituting regular safety audits creates accountability and reveals areas that need improvement. By assessing compliance with safety protocols, companies can make informed decisions regarding additional training or adjustments to processes.

Involving Employees in Safety Discussions

Creating a culture of safety requires the involvement of all employees. Encourage team members to participate in safety meetings and share their insights on improving safety protocols. Empowering employees to speak up not only strengthens safety measures but also fosters a sense of ownership within the team.

Keeping Emergency Preparedness in Mind

Establishing Clear Emergency Protocols

Every warehouse setting should have well-defined emergency protocols in place. Ensure that all employees are trained on what to do in the event of a fire, medical emergency, or natural disaster. Regular drills will help reinforce these protocols and keep employees prepared.

Access to First Aid Kits and Training

Accessible first aid kits and training can save lives in emergency situations. Make sure that kits are stocked and well-maintained, and identify employees who are certified in first aid and CPR.

Promoting a Culture of Safety

Encouragement and Recognition

Recognizing employees who practice safety diligently can promote a positive safety culture. Reward systems like ‘safety bonuses’ or quarterly recognition programs can motivate team members to prioritize safety in their day-to-day activities.

Open Communication Channels

Encouraging open communication regarding safety issues fosters an environment where employees feel comfortable reporting unsafe conditions or potential hazards. Make it easy for workers to voice concerns and be actively involved in discussions about safety improvements.

Conclusion: A Commitment to Safety Equals A Commitment to Efficiency

Emphasizing safety in warehouse operations is not just about compliance; it’s about creating a productive and healthy work environment. By implementing these essential safety guidelines, businesses can significantly minimize the risk of accidents and, consequently, drive efficiency. The investment in worker safety is an investment in operational success, reinforcing the idea that when employees feel safe, they can work at their best.

Start taking these steps today, and watch as your warehouse transforms into a safer, more efficient space for everyone involved.