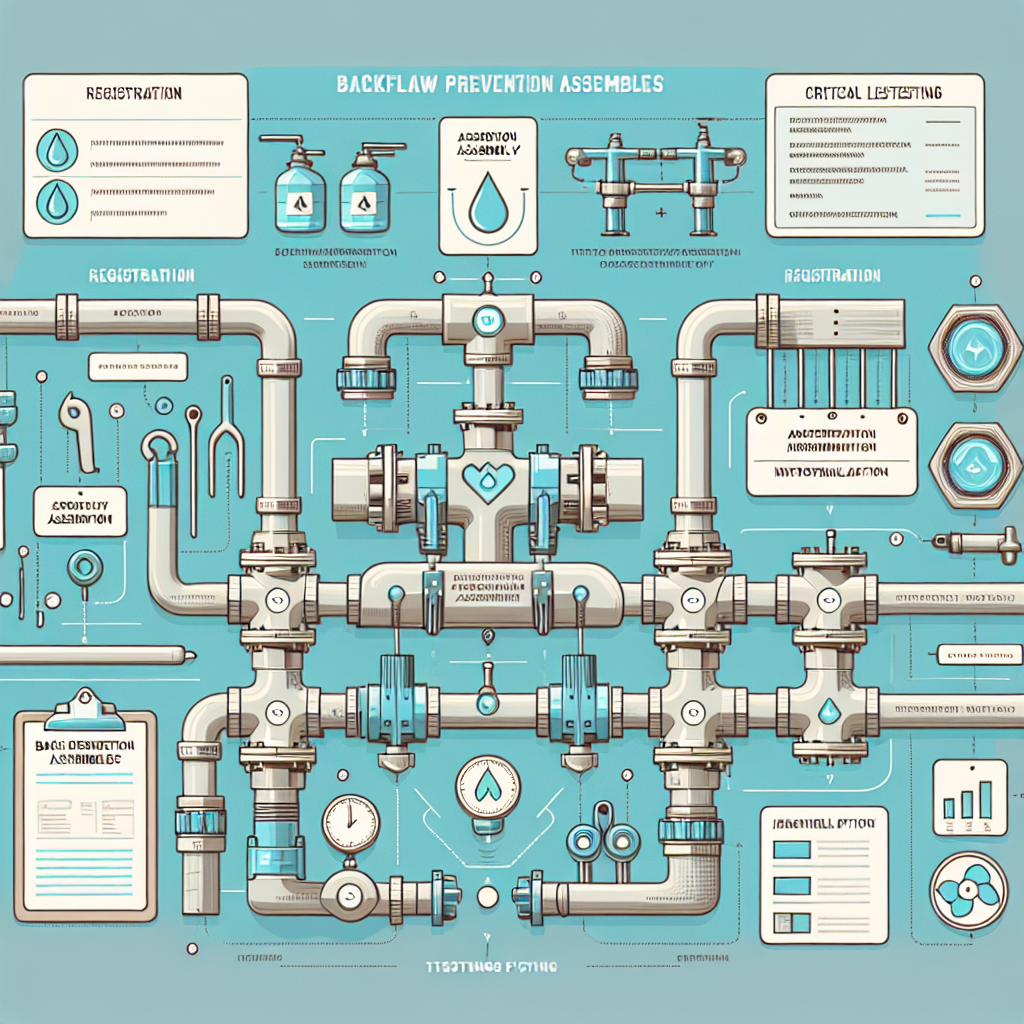

Backflow prevention assemblies play a crucial role in protecting our water supply from contamination. With growing concerns over water quality, understanding how these systems work is more important than ever. In this comprehensive guide, we break down everything you need to know about backflow prevention assemblies, from registration to testing.

What is Backflow?

Backflow occurs when contaminated water flows backward into clean water supplies. This can happen due to changes in water pressure, which might be caused by a burst pipe or excessive water demand. In short, backflow can undermine the purity of our drinking water and present serious health risks.

Understanding Backflow Prevention Assemblies

Backflow prevention assemblies are specialized devices designed to prevent the reverse flow of contaminated water into potable water systems. They are essential for maintaining the integrity of water supplies in various settings, including residential, commercial, and industrial environments.

Types of Backflow Prevention Assemblies

Several types of assemblies are commonly used, each tailored to specific scenarios:

-

Double Check Valve Assembly (DCVA): Ideal for low-risk applications, this assembly contains two check valves in series, preventing backflow when functioning correctly.

-

Reduced Pressure Zone Assembly (RPZ): Generally reserved for higher-risk environments, the RPZ incorporates a pair of check valves and a pressure relief valve to ensure comprehensive protection against backflow.

- Pressure Type Vacuum Breaker (PVB): This assembly provides protection against backflow due to siphonage. It’s typically used in irrigation and sprinkler systems.

The Importance of Registration

To effectively manage and monitor backflow prevention assemblies, many local jurisdictions require registration. This process helps ensure that the systems are properly installed, maintained, and tested.

Why Register Your Backflow Prevention Assembly?

-

Legal Compliance: Most regions enforce regulations that mandate the registration of backflow systems. Non-compliance may lead to fines and other penalties.

-

Public Health: Registration helps water authorities keep track of assemblies, ensuring that they are consistently tested and maintained to protect public health.

- Insurance: Some insurance policies may require proof of compliance with local water regulations. Registration can simplify this process.

Testing Your Backflow Prevention Assembly

Testing is a critical element in ensuring that backflow prevention assemblies operate effectively. Regular testing can identify potential failures before they cause issues, safeguarding your water supply.

How Often Should You Test?

Local regulations often dictate testing frequency, but as a general rule, backflow prevention assemblies should be tested at least once a year. Some areas may require more frequent inspections, especially for high-risk environments.

The Testing Process

-

Hire a Certified Tester: Enlist a certified backflow tester who understands local regulations and can conduct the test safely and accurately.

-

Perform Visual Inspection: The tester will start with a comprehensive visual examination of the assembly to check for signs of wear, leaks, or physical damage.

-

Conduct the Test: The tester will carry out specific tests to measure the performance of the assembly using specialized equipment.

- Documentation: After testing, the results will be documented. A copy should be submitted to your local water authority, while you keep another for your records.

Signs Your Backflow Assembly Needs Attention

Regular maintenance can extend the life of your backflow prevention assembly. However, certain signs indicate that your system may need immediate attention:

-

Visual Damage: Any visible leaks or physical damage could compromise the assembly’s integrity.

-

Diminished Water Pressure: A decrease in water pressure can signal a failure in the assembly, allowing potential backflow.

- Unexpected Contamination: Changes in water taste, color, or odor may indicate contamination, prompting an inspection.

Conclusion

Understanding backflow prevention assemblies is vital for every homeowner and business owner. From registration to testing, these systems provide essential protection against water contamination. By staying informed and proactive, you contribute to the safety of your water supply and the health of your community.

For further information or to get your backflow prevention assembly tested, contact your local water authority or a certified backflow specialist today. Together, we can keep our water clean and safe for all!