Water is one of our most vital resources, and maintaining its quality is paramount for health and well-being. Contaminated water can pose serious risks to humans and the environment alike. One crucial component in safeguarding our water supply is backflow prevention. In this article, we will explore the importance of backflow prevention assemblies, their types, and how to select the right one for your needs.

What is Backflow and Why is it a Concern?

Backflow occurs when water flows in the opposite direction from its intended path. This can happen due to changes in pressure within a water system, allowing contaminated water to flow back into clean water supplies. Common sources of backflow include irrigation systems, industrial processes, and even household plumbing fixtures.

Ingesting contaminated water can lead to health issues ranging from mild gastrointestinal upset to severe diseases. Consequently, backflow prevention is not merely a regulatory requirement; it’s an essential practice for public health.

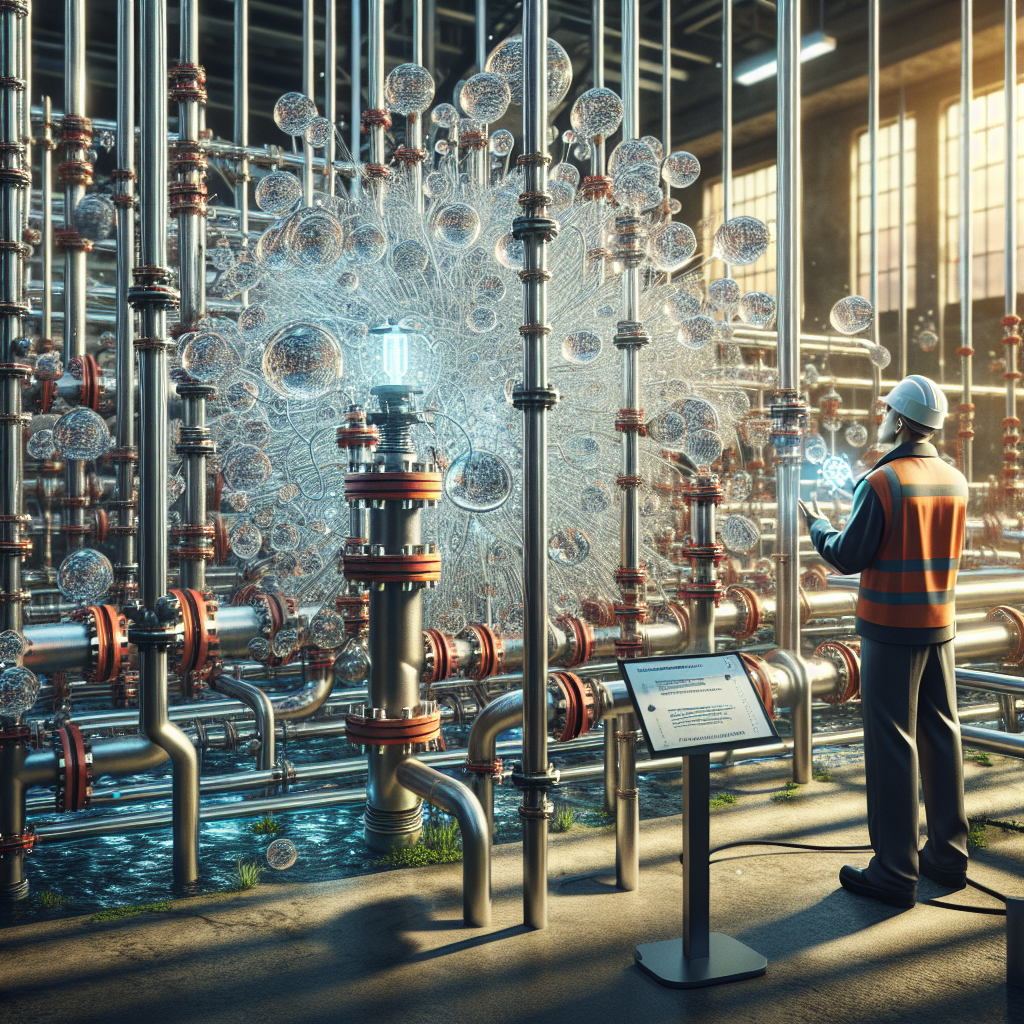

Understanding Backflow Prevention Assemblies

Backflow prevention assemblies are installed in various water systems to prevent backflow from occurring. They act as barriers, stopping contaminated water from reversing direction and entering clean water lines. Understanding the different types of assemblies is key to making an informed decision.

Types of Backflow Prevention Assemblies

-

Air Gap: This is the simplest form of backflow prevention. It involves a physical vertical space between the water outlet and the flood level of a fixture, ensuring that even if backflow occurs, contaminated water cannot reach the clean supply.

-

Double Check Valve Assembly (DCVA): This system consists of two check valves and is designed to prevent backflow in low-risk applications. It’s often used in residential plumbing systems and irrigation systems.

-

Reduced Pressure Zone Device (RPZD): This sophisticated assembly offers a higher level of protection and is required in higher-risk situations, such as in commercial settings where there is potential for hazardous substances to enter the water supply.

- Pressure Vacuum Breaker (PVB): Designed for irrigation systems, a PVB allows air to enter the system if a drop in pressure occurs, effectively preventing backflow.

Factors to Consider When Selecting Backflow Prevention Assemblies

Choosing the right assembly requires careful consideration of multiple factors to ensure maximum efficiency and compliance with local regulations.

1. Risk Assessment

Understanding your specific water system and identifying the potential risks of contamination is the first step. High-risk situations, such as those involving chemicals, require more robust solutions like RPZD devices. Conversely, lower-risk residential systems may find a DCVA sufficient.

2. Local Regulations and Codes

It is essential to keep local regulations in mind. Many municipalities have strict guidelines on the types of backflow prevention assemblies required for various applications. Consult with local authorities to ensure compliance.

3. Maintenance Requirements

Different assemblies come with varying maintenance demands. RPZ devices, for example, require regular testing and maintenance by licensed professionals. If you’re not equipped for frequent upkeep, a simpler system may be more suitable.

4. Installation Considerations

Some backflow assemblies are more complex to install than others. Hiring a professional plumber ensures that the installation is done correctly, but it’s vital to consider costs associated with both installation and potential future maintenance.

Benefits of Selecting the Right Backflow Prevention Assembly

Investing time and resources into selecting the appropriate backflow prevention assembly offers several significant benefits, including:

1. Protection of Public Health

The most critical advantage is the protection of public health. A well-chosen backflow prevention assembly drastically reduces the risk of contaminants entering the water supply, ensuring that the water you and your community rely on remains clean and safe.

2. Compliance with Regulations

By opting for the correct assembly, you ensure compliance with local laws, avoiding potential fines and legal complications. This proactive approach demonstrates a commitment to responsible water management.

3. Cost-Effectiveness

While it may seem tempting to go for the cheapest option, the long-term savings from selecting the right assembly can be substantial. Fewer maintenance issues, lower health-related expenses, and avoiding potential contamination crises can save considerable resources.

Conclusion

Maintaining water integrity is a shared responsibility that begins with selecting the right backflow prevention assembly. By understanding your specific needs, considering local regulations, and investing in proper installation and maintenance, you can protect your water supply from contamination.

In a world increasingly aware of environmental and public health issues, ensuring clean and safe water for everyone is not just a task—it’s a commitment. Let us take that commitment seriously and prioritize the integrity of our most precious resource: water.