Water safety is paramount in every community, be it residential, commercial, or industrial. One critical aspect of maintaining this safety is backflow prevention, a necessary mechanism that ensures clean water systems remain uncontaminated. In this guide, we will delve into backflow prevention, exploring its importance, the various assembly types, and best practices to ensure optimal performance.

What is Backflow Prevention?

Backflow prevention is a method used to stop the reverse flow of water, which can lead to contamination of potable water supplies. When the water flows in the opposite direction, it can carry harmful substances, pollutants, or pathogens into the clean water system. Understanding backflow and its prevention is essential for safeguarding public health.

Why is Backflow Prevention Important?

Protecting Public Health

The primary goal of backflow prevention is to protect public health. Contaminated water can lead to serious illnesses, and an efficient backflow prevention system ensures that your drinking water retains its quality. This is particularly crucial in areas with a history of waterborne diseases.

Compliance with Regulations

Most regions have strict regulations regarding water safety. Implementing backflow prevention systems is often a legal requirement. Failure to comply can result in fines and enforcement actions from local health boards.

Cost-Effective Solution

Investing in backflow prevention is a cost-effective choice. The cost of treating contaminated water and repairing the infrastructure can far exceed the expenses associated with installing and maintaining backflow prevention devices.

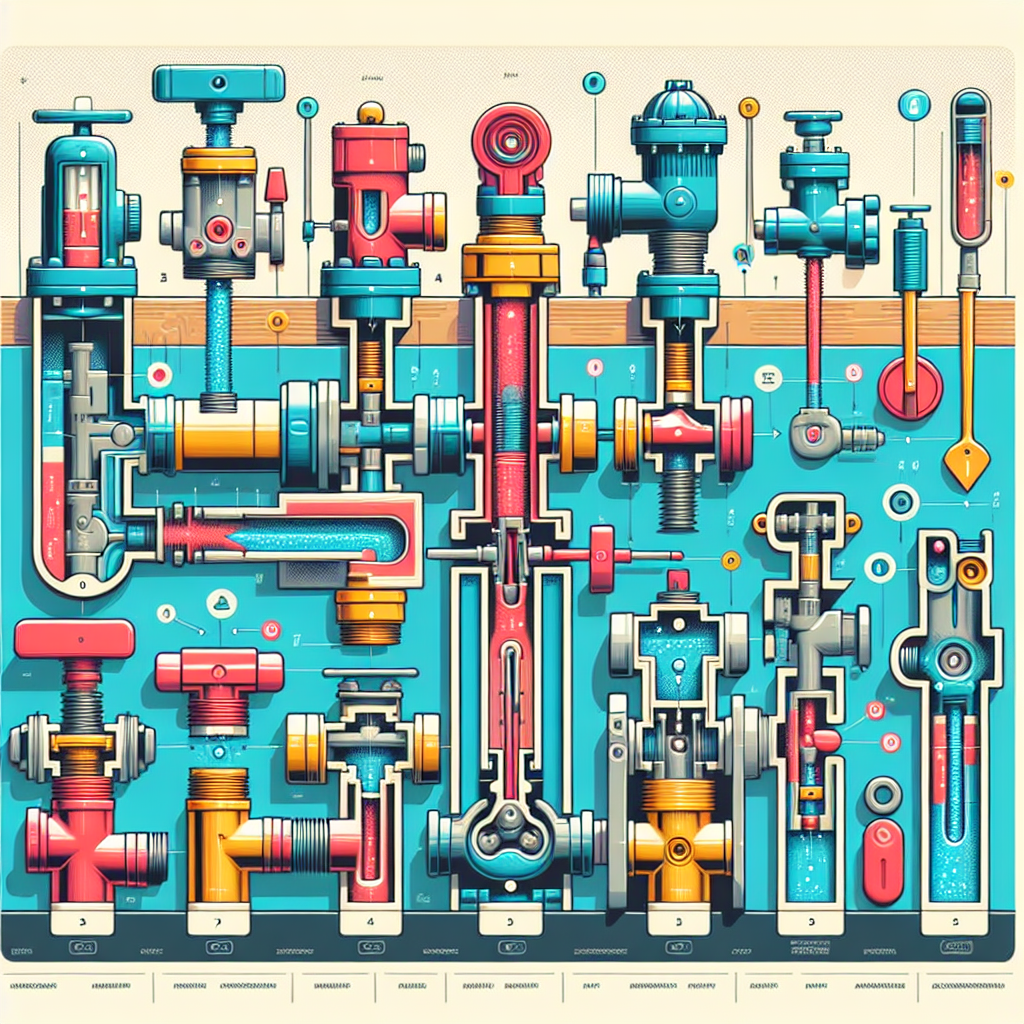

Types of Backflow Prevention Assemblies

Understanding the different types of backflow prevention assemblies is crucial to selecting the right one for your specific needs. Here’s a detailed look at the most common types:

1. Reduced Pressure Zone (RPZ) Assemblies

Reduced Pressure Zone (RPZ) assemblies are among the most effective backflow prevention devices. They operate by creating a pressure drop that prevents backflow. RPZ assemblies are ideal for high-hazard applications where there is potential risk of contamination, such as chemical facilities or irrigation systems.

Key Features:

- Two check valves with a pressure differential relief valve

- Suitable for high-risk environments

- Requires regular maintenance and testing

2. Double Check Valve Assemblies

Double Check Valve Assemblies (DCVAs) are another popular option for backflow prevention. These devices consist of two check valves arranged in sequence to provide an extra layer of protection against backflow.

Key Features:

- Effective for low to moderate hazard situations

- Simpler maintenance routine compared to RPZ

- Usually less expensive than RPZ systems

3. Pressure Vacuum Breakers (PVB)

Pressure Vacuum Breakers (PVB) are primarily designed for irrigation systems. They operate by breaking the vacuum that occurs when water pressure drops, preventing backflow into the potable water system.

Key Features:

- Cost-effective and easy to install

- Best suited for non-potable applications

- Must be installed above the highest water outlet

4. Atmospheric Vacuum Breakers (AVB)

Similar to PVBs, Atmospheric Vacuum Breakers (AVBs) are designed to prevent backflow. They allow air to enter the system, breaking the vacuum and preventing potential contamination.

Key Features:

- Simple design and low maintenance

- Not suitable for continuous pressure situations

- Effective in low-hazard applications

Best Practices for Backflow Prevention

Regular Maintenance and Testing

To ensure the effectiveness of your backflow prevention devices, regular maintenance and testing are crucial. This helps you identify potential issues before they become significant problems.

Professional Installation

It is essential to hire a qualified professional for the installation of backflow prevention assemblies. Proper installation ensures that the devices function as intended and meet local code requirements.

Educate Your Community

Raising awareness about backflow prevention within your community can play a significant role in water safety. Consider organizing workshops or informational seminars to help residents understand the importance of these systems.

Stay Informed

Regulations and technologies regarding backflow prevention can change. Make sure to stay informed about the latest standards and innovations. Subscribe to industry publications, attend conferences, and engage with local health departments.

Conclusion

Backflow prevention is an essential aspect of maintaining clean water systems and protecting public health. By understanding the different types of backflow prevention assemblies and implementing best practices, you can ensure the safety of your water supply. Prioritizing backflow prevention not only meets regulatory requirements but also contributes to the overall well-being of your community. Remember, clean water is a precious resource we must all protect.